Handling and dosing that’s what it is all about when designing and engineering incinerators for gas, fluids, or solids and in any combination with biomass, waste or sludge's.

我们可以承担多种焚烧炉的工程及设计,包括处理气体,液体,固体及任何组合的有机物 垃圾或淤泥的焚烧炉。

With our years of experience as warranty, but also with the solid guarantee of the turn-key conditions, we erect at your site an industrial incinerator as a package unit from our workshop which will be made under the applicable regulations. We can offer you the design, engineering, manufacture, testing at our workshop, the supply, the installation on site and finally the commissioning of a complete industrial incinerator.

以我们多年的实践经验,保证提供您一个安全可靠的交钥匙工程。我们在车间内按规范完成 焚烧炉设备包的工程设计,制造,和检验,然后在现场进行安装,最后通过试车完成整套焚 烧炉的施工过程。

This incinerator will meet the governments, yours and our specifications. It will perfrom as requested and save you money, for years to come.

焚烧炉项目满足当地政府,业主和公司的相应规范,根据需要进行操作,为您将来的数年节 省资金。

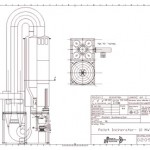

Solid incinerator 固体焚烧炉

Our products including:

我们的产品包括:

- Waste incineration.

垃圾焚烧

- Thermal processing of hazardous waste.

有害垃圾热处理

- Activated carbon incineration and mercury recovery.

活性炭焚烧炉和水银回收

- Incineration of granulates.

颗粒物焚烧

Fluidised and spouting bed incinerators, especially designed for wastes with a low melting point of the ashes.

喷射式流化床焚烧炉,专门为低熔点飞灰垃圾设计

All these applications get great benefit from our spouting bed technology. Spouting bed Incinerators have the advantage that no unwanted clogging and/or melting of ashes will occur. Every particle will be combusted floating in the air flow and will be surrounded with sufficient oxygen for a complete combustion. The temperature at every spot in the incinerator can be adjusted within 5 degrees.

所以这些应用得益于我们的喷射流化床技术。喷射式流化床的优点是不会发生飞灰熔化而引 起的不必要堵塞。每一个颗粒都会浮在空气流中并被点燃,并被氧气包围,这样确保充分燃 烧。在焚烧炉里每一点的温度可在5 度内调整。

This feature made this type of incinerator ideal to destroy dioxins in activated carbon deriving from the flue gas filters of a communal waste incinerator plant in Rotterdam.

这种焚烧炉的特点非常有利于在活性炭中处理尾气中的二恶英物质,鹿特丹的公共垃圾焚烧 工厂就是很好的例子。

After scrubbing, the flue gas, deriving from the communal waste incineration plant, is treated with an activated carbon filter to extract the dioxins and other components that slipped through the scrubbers. Nice side effect; the working efficiency of the gas cleaning plant is consequently increased to almost 100 %. The polluted activated carbon, from the filter has to be treated and dosed to be processed in this specialized spouting bed Incinerator to ensure no dioxins leave the process in any form.

在鹿特丹工厂,从垃圾焚烧炉里出来的废气经过水洗塔洗涤后,再通过一个活性炭过滤器去 除二恶英及其它从洗涤塔漏掉的有害成份,这是很好的辅助过程,可以使气体清洁厂的工作 效率提高了100%。过滤器中被污染的活性炭再被送到这种特殊的喷射床焚烧炉中焚烧,确 保整个生产过程无任何形式的二恶英流出。

The process is unmanned and fully controlled by a PLC.

整个生产过程都是无需人力,所有操作都在PLC 上完成。

Recirculation of flue gas is relatively simple and in the case a combustor is used as incinerator room, within 5 minutes after the start command the incinerator can be on line.

废气的循环系统相对来说比较简单,在这种情况下燃烧炉被当作是焚烧炉的燃烧室,开启命 令5 分钟后,焚烧炉开始工作。

Spouting bed Incinerator to recuperate heavy metals, such as mercury deriving from activated carbon contained in waste laboratory filters.

喷射床式焚烧炉还可以用来回收重金属,例如从废弃的活性炭中回收水银。

Liquids and Sludge's incinerator 液体和淤泥焚烧

Liquid waste and all kinds of sludge’s are expensive to be processed by third parties. At a certain yearly amount it will be economically viable to process this residue at your own plant and under your own responsibility. Sometimes however, handling and drying of sludge can be very difficult due to a sticky faze at a certain dry solids contend.

液体废料和各种淤泥如果交由第三方处理,会产生很高的费用。长远 来看,如果自己负责在 厂区里处理这些垃圾,是个切实可行并比较经 济的办法。但是由于在干燥的固体中有黏着物 质,有时处理和干燥淤泥的过程变得比较困难。

When possible, we better avoid that sticky situation, by integrating drying and incineration in one step of the combustion process.

我们会通过在燃烧过程中控制干燥和焚烧同时进行,尽可能地避免黏 着现象发生。

Spouting bed Incinerators, typically cope with that situation.

喷射床式焚烧炉在这种情况下使用,效果非常好。

The sludge is fragmented, atomised and subsequently directly dosed into the incinerator room.

淤泥被打碎,喷成雾状,然后直接注入到焚烧室内。

Floating in the hot air flow inside the incinerator, every particle will be dried and subsequently combusted, while surrounded with sufficient oxygen for a complete combustion. The temperature at every spot in the incinerator can be adjusted within 5 degrees, making the handling of ashes considerable less complicated.

在焚烧炉里,每个颗粒都漂浮在热气流中,被干燥的同时点燃。焚烧 内每一点的温度可以 在5 度之内调整,这样使处理飞灰过程变得简单。

The process is unmanned and fully controlled by a PLC.

整个过程不需要人力,全部在PLC 上控制完成。

Recirculation of flue gas is relatively simple and in the case a combustor is used as incinerator room, within 5 minutes after the start command the incinerator can be on line.

废气循环系统相对简单,在这种情况下燃烧炉作为焚烧室,在启动5 分钟之后,焚烧炉开始工作。

Vapors and combinations

蒸汽及混合物

This equipment will bring a solution for all kinds of problems with odorous, toxic and/or hazardous gasses or air derived from production processes as there are e.g. dryers, oil refineries, cooking stoves, printing presses, wax melting and many other product lines.

这种设备能够处理多种有气味的,或有毒有害的工艺废气,例如从干 燥器,精炼油,烹饪炉,印刷打印机,蜡熔等生产过程中排放的尾气。

Incinerator for highly hazardous waste, mainly containing hydrocarbon solvents and purge nitrogen safety lines.

焚烧炉还用于处理高危险性的废气,主要含有碳氢化合物溶剂,安全 管线清扫的氮气尾气。

Fume incinerator at foundry, installed on top of the ovens. Lost wax form process with aluminum and titanium. Very high loads of hydro-carbons, up to 2 kg/sec.

铸造厂的烟气焚烧炉安装在炼炉上,处理熔模铸造所产生铝和钛,碳氢化合物含量很高,达 到2 kg/sec.

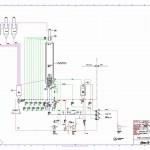

EXD / ATEX / Explosion prevention

As Pulse combustors use explosions to function, a robustly build unit is a condition. And as they are self venting, they easily can be shielded off from their environment.

This makes them perfectly fit to be used in high risk explosion zones.

- Liquid Propane filling station.

- Evacuation gas incinerator for filling station at commissioning.

- Zone 0 Incinerator Explosion proof incinerator for hazardous waste

- Incinerator for an offshore oil storage tanker

![Container[1] Container[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/Container1-150x150.jpg)

![BENEG1[1] enclosed de gasser ATEX](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/BENEG11-150x150.jpg)