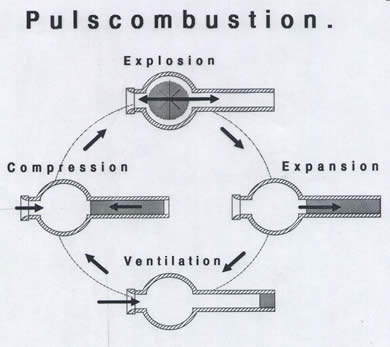

A fan only used during starting, blows fresh air into the explosion chamber. In the same time fuel is admitted and a spark-plug is put into operation.

刚启动时通过风机把新鲜空气送入燃烧室,同时吸入燃料,并打开火花塞。

When the explosion limit is reached the mixture will explode. While expanding, the gasses flow through the inlet and outlet pipes. The outlet pipe being greater in length than the inlet pipe causes, due to the inertia of the exhaust gasses, as they travel through the outlet pipe, an under pressure in the explosion chamber. This under pressure tows in fresh air and fuel and also forces the exhaust gasses to slowdown and even changes their direction, thus making them move back to the explosion chamber. In the explosion chamber the new mixture collides with these old, still burning exhaust gasses, and therefore is compressed and ignited. A new explosion occurs. This makes the cycle complete.

当混合物浓度达到爆炸极限时开始爆炸,同时扩散,气体流向进口管道和出口管道。出口管 道的长度比进口管道长,由于废气的惯性运动,当流过出口管道时,燃烧室里产生负压,负 压的作用使新鲜的空气和燃料又被吸入到燃烧室,同时废气扩散速度降下来,甚至改变流动 方向,又回到了燃烧室。在燃烧室内新旧混合物发生碰撞,废气继续燃烧,压缩和点燃,新 的爆炸发生,这样一个循环就完成了。

Fan and ignition are no longer needed to continue the process. The combustor is in action without ignition, ventilation and other supporting energy, more or less like a diesel engine.

风机和点火器不再需要维持这个过程,燃烧炉启动后不需要点火,放空和其它辅助能源,原 理有些像柴油发动机。

In the lower power output range, from 10 up to 100 kW, often the inlet opening is intermittently closed by gas flow controlled back pressure flapper valves. In the upper range from 100 kW up to 10 MWatt, mostly no mechanical valves, but aerodynamic valves are used so no moving parts are necessary.

在10KW 到100KW 低功率输出范围内,使用翻板阀通过气流的被压控制迅速关闭进口。在 100KW 到10MKW 高功率输出范围内,一般不使用机械阀门,采用气动阀门,不需要任何 运动部件。

The advantages of Pulse combustion:

脉冲燃烧的优点:

Pulse combustion prevents, in heat exchangers normal boundary layers, because of the high and alternating exhaust gas velocities. Therefore the transfer of heat is much higher than in non pulsating combustion. A heat exchanger of noticeable smaller size can be used. (k = 100 - 500 W/m2 /K)

由于脉冲燃烧时交替的高速废气流动,可以避免像换热器那样的边界层产生,因此热交换速 率要比非脉冲燃烧高很多,因此热交换器的体积明显变小。(k = 100 - 500 W/m2/K)

No deposits will form in the combustion chamber and/or the heat exchanger also due to the pulsating stream and high velocity of the gas.

由于气体的脉冲流和高流速,燃烧室内没有沉淀物。

When the Pulse combustor is of the high efficiency condensing type the condensation water is transferred easily to the exhaust decoupling chamber.

当脉冲燃烧器用于易冷凝的介质时,冷凝液能很容易进入分离室内。

The explosion and pulsation's provide for an excellent mixing of fuel and air. The air to fuel ratio may be low. ( Lambda = 1.0 -1.1 )

由于爆炸和脉动使空气和燃料能很充分混合,这样空气对燃料的比值可以很低,( Lambda =1.0 -1.1 )

Very low levels of CO and NOx are found In the exhaust gasses. ( 0-10 ppm CO and 0-70 mg/m3 NOx ) With regard to the environment, Pulse combustion contributes only modestly to the acid rains.

废气中CO 和NOx 含量也很低(0~10ppm CO, 0~70mg/m3 NOx).对于大气环境来说,脉冲 燃烧在大气只产生适量的酸雨。

Both gas and fluid fuels and even solid fuels can be used for a Pulse combustor. In the field of waste disposal this is of great importance. ( Bio gas, chemical waste, manure, coal and solid wastes.)

脉冲燃烧器可以利用气体,流体甚至固体燃料,这在垃圾处理领域非常重要(生物气体,化 学垃圾,粪便,煤渣和固体垃圾)

A wide variation in the "Wobbe index" can be tolerated.

适用燃料的华白指数范围很广。

A stack or chimney is not necessary. The gasses being low in temperature and under some pressure can be disposed of trough small plastic pipes. For example a 20 kW combustor only needs a exhaust pipe of 30 mm. diameter.

不需要设置烟囱,由于气体温度和压力不高,可以通过塑料管道处理。例如像一个20KW 的燃烧炉,只需要设置一个直径为30mm 废气排放管道就可以了。

High combustion chamber loads are possible. ( 10.000 - 50.000 KWatt/m3 ) This results in small dimensions. In combination with the high heat transfer nevertheless the combustion temperature is relatively low. ( 1300 - 2000 K ). A 20 KWatt pulse combustor has an explosion chamber of 80 x 80 mm. whereas in an explosion chamber of only 400 x 500 mm. 5 Mw. may be generated.

燃烧室的热负荷可能很高。( 10.000 - 50.000 KWatt/m3 ),这样燃烧室的体积很小。相对于 如此高的传热效率,燃烧温度较低( 1300 - 2000 K ).一个20 KWatt 的脉冲燃烧器的爆炸室 体积是80 x 80 mm. 然而一个400 x 500 mm.的爆炸室可以产生 5 MWatt 的热量。

The Pulse combustion devices, being thoroughly explosion save can be installed in highly dangerous surroundings, as in explosion zone 0.

脉冲燃烧装置是安全防爆,可以安装在高危险的环境下,例如0 区防爆等级的地方。

The pulse combustors may be engineered in such a way that no losses occur due to the heating of air after the combustor is put out of action. Also the losses due to auxiliary power are extremely low. ( Pulse combustors are self ventilating. )

脉冲燃烧器这种设计结构,即使在燃烧器后的加热空气出问题,或者辅助电源很低的情况下,也不会有任何热损失。

Pulse combustors are very suitable for drying purposes. They produce inert exhaust gas of a high temperature and highly oscillating.

脉冲燃烧器非常适合用于干燥为目的的生产,能产生高温且高振荡的惰性尾气。

Apart from all these advantages of course some disadvantages exist. First the high level of sound that is produced by the explosions is really annoying. Also the internal feedback of the oscillating gasses can be a problem. Both items are setting high demands to the product development and the engineering. Nowadays the problems can be solved due to the more thoroughly and extended know-how on pulse combustion.

除了这些优点外,还有一些不足的地方。首先爆炸产生的高噪音是令人烦恼的事。其次内部 气体碰撞引起的回声也是难题。这两点为产品的开发和设计提出更高的要求。现在通过对脉 冲燃烧的更深入的研究和实践,已经能解决这些问题。

![pulsecombustor10[1] pulsecombustor10[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/pulsecombustor101-150x150.jpg)

![aken[1] Burners](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/aken1-150x150.jpg)